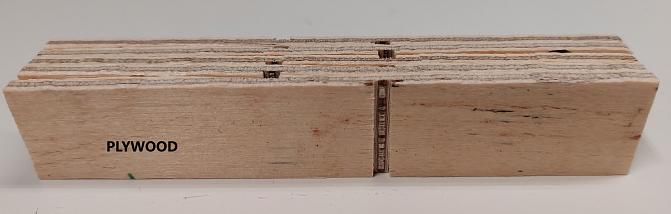

Biobased sustainable adhesive system for plywood, LVL, and wood-based panels

On this page

Luke has developed a new and inventive method, Nature2Bond, to produce sustainable and non-toxic bio-glues that have a potential to replace the formaldehyde adhesives in the production of woodpanels. This cost effective method is fully run by forest industry side streams.

Allow functional cookies to show the embedded media.

Challenge

Plywood/laminated veneer lumber and wood-based panels (particleboard and fiberboard) are the major forest-based industries in Finland as well as globally. In production of these wood products, the adhesives systems (phenolic resins and amino resins) are depending on the fossil-derived materials or chemicals. These current adhesives are not only unsustainable, but they also emit toxic formaldehydes during their service life, for example urea formaldehyde resin.

Industries are constantly looking for the suitable replacement of current adhesives, which would exhibit versatile properties such as flexibility, low cost, high thermal stability, water, and chemical resistance. Although new solutions are introduced in the early stages of market development, there remains a need for a robust and sustainable, cost effective and simple production method for a bio-glue product line, which is free from toxic components and independent on fossil materials.

A new method produces cost effective, sustainable bio-glue

Natural Resources Institute Finland (Luke) has developed a new and inventive method to produce biobased, sustainable and non-toxic bio-glues that have a potential to replace the formaldehyde-based adhesives in the production of panels. The performance of Luke’s adhesive is comparable with current adhesives, and it meets the toughest standards requirements of plywood/LVL performance.

Non-toxic, bio-based glue is suitable for indoor and outdoor use

Luke’s process is straightforward, cost-effective and can utilize abundant supply of renewable raw materials. Using the new production method several intermediate steps of purification and functionalization can be avoided, which results in cost savings. New bio-glues are suitable to be used in exterior grade wood panels as well as in interior grade wood panels.

The solution developed by Luke follows the principles of circular bioeconomy; low-value raw materials are processed into high value-added products and wood panels bonded with new bio-glues are sustainable and environment friendly.

IPR status

The Nature2Bond project funded by Business Finland and Luke aims to find the best possible commercialization route for the method and the adhesive product. Patenting of the technology in progress. Would you like to hear more about Nature2Bond? Please contact us and let's talk more!